What is Boiling Liquid Expanding Vapour Explosion (BLEVE) on Gas Carrier Ships?

Just like Air Locks on Gas Carrier, a safety protection system between the deck (the hazardous zone) and the cargo compressor motor (gas free zone), the cargo tanks of gas carriers are also provided with various safety measures to prevent contact of cargo with the atmosphere and also to avoid cargo tanks from getting over pressurised.

Gas carrier’s cargo tanks are specially made of high strength and low thermal coefficient materials with insulation and safety systems. One of the essential safety measures in such cargo tanks is the pressure relief valve, which helps in avoiding over pressurisation of tanks and preventing rupture and damage of the same.

In gas ships, it is not the liquid which generally catches fire but it’s the vapour of the liquid which is more dangerous when evaporates at very low temperature. This results in Boiling Liquid Expanding Vapour Explosion (BLEVE).

What is Boiling Liquid Expanding Vapour Explosion (BLEVE)?

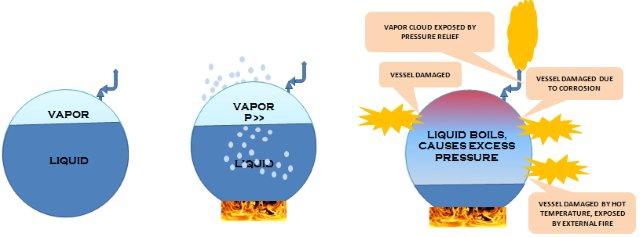

BLEVE is a vapour explosion which may result from catastrophic failure of a tank structure, which was containing cargo liquid above the boiling point at nominal atmospheric pressure.

The cargo in the tanks of gas carrier is partially liquid and partially vapour in normal condition. However, when the tank structure collapses, the vapour tries to escape or leak through the opening, resulting in decrease in the pressure inside the tank. These drastic lowering of pressure inside the cargo tank results in rapid boiling of liquid and increase in vapour formation.

The pressure of the escaping vapour becomes very high and leads to a shock wave or explosion in presence of a fire source, completely destroying the tanks structure and surrounding areas.

Common Causes of BLEVE:

The most common reason which leads to BLEVE is fire near tanks containing gas cargo such as propane. Because of the high temperature of the surrounding, the tank temperature starts to increase and the inside of the tanks gets over pressurised. The high pressure inside the tank will be generally released by the relief valve.

However, if the pressure builds up rapidly because of high temperature and high rate of heating in the surrounding, the tank will collapse at the weaker point, exposing pressurised and flammable vapour to the naked flame and leading to Boiling Liquid Expanding Vapour Explosion.

Reason for Failure of Tank Structure:

- Improper maintenance of tanks

- Corrosion of the tank structure

- Relief valve of the tank is malfunction or stuck

- Mechanical damage to the tank

- Material failure

- Tank structure severely exposed to flame or fire

Precautions to avoid BLEVE

- Maintenance of the cargo tank at regular interval

- Relief valve to be functional at all time

- The size of the relief valve to be fitted should be as per the International Gas code

- Emergency preparedness of all ship staff

- Always think of safety first

No comments:

Post a Comment